-

1" Schedule 80 PVC Elbow - Socket (806-010)

$3.22Unit price /Unavailable -

2" Schedule 80 PVC Elbow - Socket (806-020)

$4.78Unit price /Unavailable -

3/4" Schedule 80 PVC Elbow - Socket (806-007)

$1.83Unit price /Unavailable -

1" PVC Male Barbed Insert Adapter 1436-010 (Inst x MPT)

$1.53Unit price /Unavailable -

1" Schedule 80 PVC (MPT x S) Male 836-010

$5.50Unit price /Unavailable -

1" Schedule 80 PVC Tee - Socket (801-010)

$4.99Unit price /Unavailable -

2" Schedule 80 PVC (S x S) Coupling 829-020

$6.09Unit price /Unavailable -

1-1/2" Schedule 80 PVC Elbow - Socket (806-015)

$3.88Unit price /Unavailable -

2" Schedule 80 PVC (MPT x S) Male 836-020

$13.44Unit price /Unavailable -

1" Schedule 80 PVC (S x S) Coupling 829-010

$3.41Unit price /Unavailable -

3/4" PVC Male Barbed Insert Adapter 1436-007 (Inst x MPT)

$1.46Unit price /Unavailable -

3/4" x 1" Sch 80 PVC Reducing Male Adapter - MPT x Socket 836-102

$7.84Unit price /Unavailable -

4" Schedule 80 PVC Van Stone Slip Flange 854-040

$26.96Unit price /Unavailable -

3/4" Schedule 80 PVC (MPT x S) Male 836-007

$3.19Unit price /Unavailable -

2" Schedule 80 PVC Tee - Socket (801-020)

$17.21Unit price /Unavailable -

1" Schedule 80 PVC (S x S) Union 897-010

$7.76Unit price /Unavailable -

3/4" Schedule 80 PVC Tee - Socket (801-007)

$4.08Unit price /Unavailable -

6" Schedule 80 PVC Van Stone Slip Flange 854-060

$46.21Unit price /Unavailable -

1-1/2" Schedule 80 PVC (MPT x S) Male 836-015

$9.28Unit price /Unavailable -

1/2" PVC Male Barbed Insert Adapter 1436-005 (Inst x MPT)

$1.23Unit price /Unavailable -

1-1/2" Schedule 80 PVC (S x S) Coupling 829-015

$5.65Unit price /Unavailable -

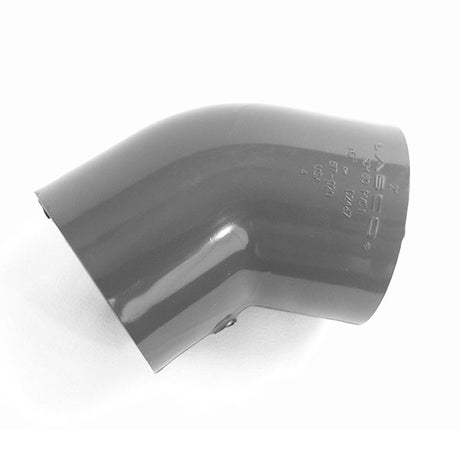

1" Schedule 80 PVC 45 Elbow 817-010

$5.90Unit price /Unavailable -

1" Schedule 80 PVC (S x FPT) Female 835-010

$5.50Unit price /Unavailable -

3" Schedule 80 PVC Van Stone Slip Flange 854-030

$21.34Unit price /Unavailable -

1-1/2" Schedule 80 PVC Tee - Socket (801-015)

$13.82Unit price /Unavailable -

3/4" Schedule 80 PVC (S x S) Coupling 829-007

$3.74Unit price /Unavailable -

1/2" Schedule 80 PVC Elbow - Socket (806-005)

$1.34Unit price /Unavailable -

3" Schedule 80 PVC Ell (S xS) 806-030

$12.79Unit price /Unavailable -

1-1/2" PVC Male Barbed Insert Adapter 1436-015 (Inst x MPT)

$2.71Unit price /Unavailable -

3/4" Schedule 80 PVC (S x FPT) Female 835-007

$3.40Unit price /Unavailable -

2" Schedule 80 PVC (S x S) Union 897-020

$23.55Unit price /Unavailable -

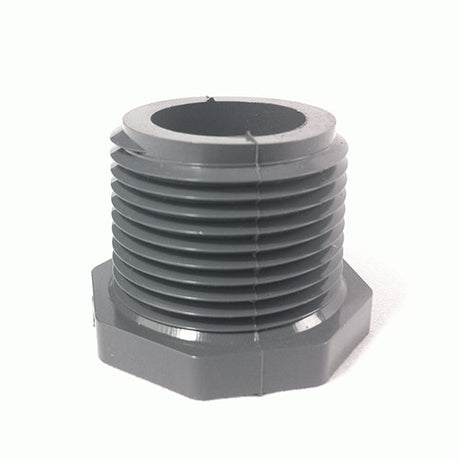

1" x 3/4" Schedule 80 Reducer Bushing 838-131

$2.34Unit price /Unavailable -

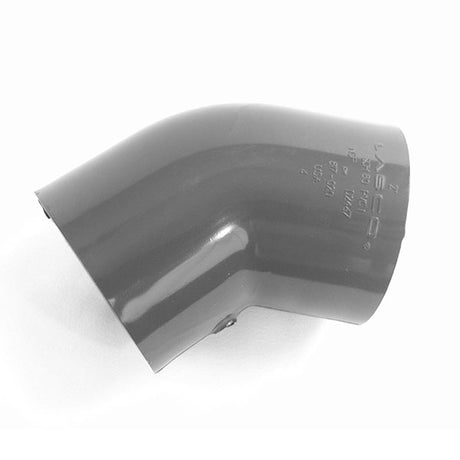

2" Schedule 80 PVC 45 Elbow 817-020

$11.54Unit price /Unavailable -

3" Schedule 80 PVC (S x S) Coupling 829-030

$17.15Unit price /Unavailable -

1/2" Schedule 80 PVC (MPT x S) Male Adapter 836-005

$2.93Unit price /Unavailable -

1-1/4" Schedule 80 PVC Elbow - Socket (806-012)

$3.68Unit price /Unavailable -

4" Schedule 80 PVC Ell (S xS) 806-040

$19.48Unit price /Unavailable -

3/4" Schedule 80 PVC (S x S) Union 897-007

$6.77Unit price /Unavailable -

2" Schedule 80 PVC (S x FPT) Female 835-020

$21.58Unit price /Unavailable -

1" x 3/4" Schedule 80 Reducer Bushing 837-131

$2.34Unit price /Unavailable -

1" x 3/4" Schedule 80 Reducer Bushing 839-131

$4.92Unit price /Unavailable -

6" Schedule 80 PVC Slip Flange 851-060

$70.82Unit price /Unavailable -

4" Schedule 80 PVC (S x S) Coupling 829-040

$21.43Unit price /Unavailable -

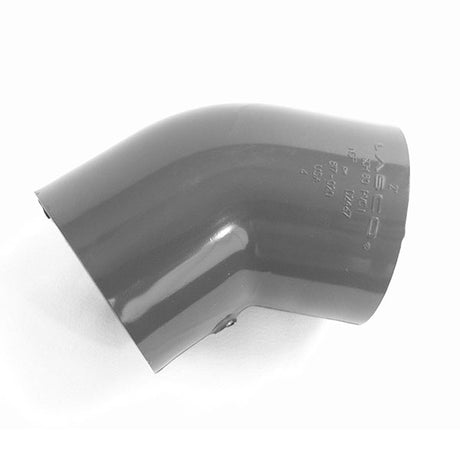

3/4" Schedule 80 PVC 45 Elbow 817-007

$3.88Unit price /Unavailable -

1-1/2" Schedule 80 PVC (S x S) Union 897-015

$17.43Unit price /Unavailable -

4" Schedule 80 PVC Slip Flange 851-040

$45.04Unit price /Unavailable -

8" Schedule 80 PVC Van Stone Slip Flange 854-080

$83.55Unit price /Unavailable -

1-1/4" Schedule 80 PVC (MPT x S) Male 836-012

$6.41Unit price /Unavailable -

3" Schedule 80 PVC (MPT x S) Male 836-030

$16.98Unit price /Unavailable -

6" Sch 80 PVC Van Stone Spigot Flange 856-060

$42.87Unit price /Unavailable