Despite seeming like a small detail, a valve's O-ring material is very important. The material can dictate the temperature tolerance of a seal. It can also give the seal certain chemical resistances, with some types of rubber being compatible with difference fluids. Two common materials for true union ball valves are Viton and EPDM.

Viton (shown in image on the right) is a synthetic rubber with a high chemical and temperature resistance. EPDM, which stands for ethylene propylene diene monomer, has its own set of properties that make it an extremely popular O-ring material. When comparing Viton vs. EPDM, several factors must be considered: temperature tolerance, chemical compatibility, and cost. Continue reading for the full comparison.

EPDM Seals

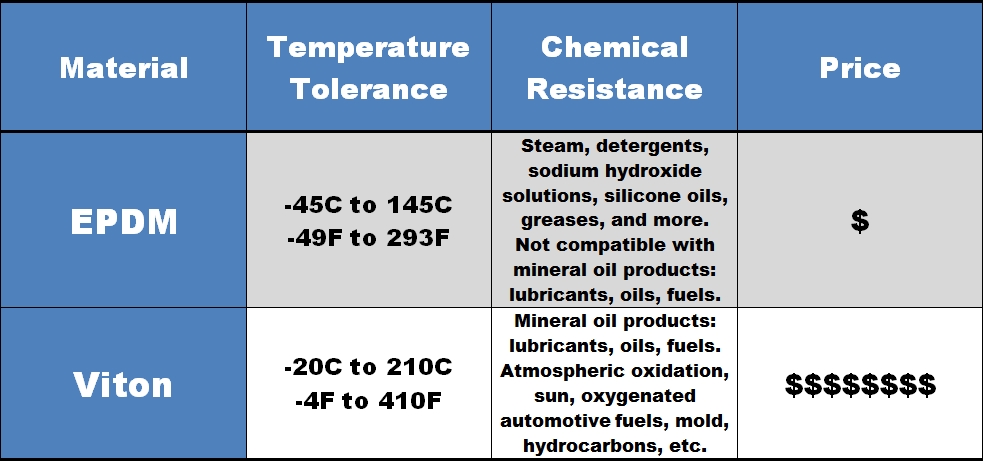

EPDM (ethylene propylene diene monomer) is a complex yet inexpensive rubber that has a wide range of uses. It is commonly used in roofing for waterproofing, as EPDM seals nicely. It is also a common material for freezer room seals, as it is an insulator and has excellent low temperature tolerance. Specifically, EPDM operates effectively in temperatures ranging from -49F to 293F (-45C to 145C), making it perfect for applications in any temperature.

While many rubbers have high temperature resistances, only a few can deal with lower temperatures the way EPDM does. This makes it the first choice for anyone trying to create a seal in a cold environment or with cold materials.  Typical applications for EPDM include electrical insulation, pond liners, tubing, solar panel heat collectors, O-rings, and more.

Typical applications for EPDM include electrical insulation, pond liners, tubing, solar panel heat collectors, O-rings, and more.

In addition to a large temperature tolerance, EPDM also has a wide range of chemical resistances. These include hot water, steam, detergents, caustic potash solutions, sodium hydroxide solutions, silicone oils/greases, and many other diluted acids and chemicals. It is unsuitable for use with mineral oil products, such as lubricants, oils, or fuels. For specific chemical compatibilities of EPDM, click here. These impressive properties, combined with how inexpensive it is, make EPDM a very popular seal material.

Viton Seals

Viton is a synthetic rubber and fluoropolymer elastomer. "Fluoropolymer" means this material has high resistance to solvents, acids, and bases. "Elastomer" is a word that is basically interchangeable with "rubber." We won't get into what distinguishes an elastomer from a rubber here, but we will talk about what makes Viton so special. This material is often characterized by its green or brown color, but what really makes it unique is its density. Viton is significantly more dense than most types of rubber, which makes Viton seals some of the strongest.

Viton has a wide temperature tolerance which ranges from -4F to 410F (-20C to 210C). The high temperatures Viton can withstand make it ideal for high temperature applications. Viton is often used in O-rings, chemical-resistant gloves, and other molded or extruded goods. O-rings made of Viton are perfect for scuba diving, automobile engines, and valves of all kinds.

When it comes to chemical resistance, Viton can't be beat. It resists corrosion from a greater variety of fluids and chemicals than any non-fluorinated elastomer. Unlike EPDM, Viton is compatible with oils, fuels, lubricants, and most mineral acids. It is also extremely resistant to compression, atmospheric oxidation, sun, weathering, oxygenated automotive fuels, aromatic hydrocarbons, fungus, mold, and more. It is also inherently more resistant to burning than most other rubbers. Read more about Viton's chemical do's and don't's here.

The main issue with Viton is its price. In production, it costs around 8 times more than EPDM to make the same amount of material. When buying a product with just a little of these rubber materials in it, the price may not vary significantly. But when ordering a large quantity, you can expect the Viton parts to be much more expensive than EPDM.

Viton vs. EPDM Seals

So which material is best? That questions isn't exactly fair. Both materials have certain applications they are perfect for, so it all comes down to the job they will be doing. Our CPVC ball check valves and CPVC swing check valves are available with Viton seals or EPDM seals. These seals are made with O-rings that fit in a joint. These valves are all designed to be easily taken apart for easy maintenance, so they have bodies that can be disassembled.

If you need a valve for a water system, regardless of temperature, a valve with an EPDM seal is usually the best option. Other than slightly different temperature tolerances, the main distinction between these two materials is their chemical resistances. Viton is great for use with fuel and other corrosive materials, but that extreme durability is unnecessary when dealing with something harmless like water.

If you want to ensure maximum durability under stressful conditions, Viton is the ideal choice. As mentioned earlier, Viton seals hold strong under almost any kind of corrosion and acidity. While EPDM is very tough in its own right, it does not compare to Viton in terms of sheer chemical resistance.

In this post, we have been pitting these two materials against each other: Viton vs. EPDM, which is better? The answer is that neither is "better" than the other. They are both great materials with endless uses. When you have to choose between them, take a look at the temperatures you will be exposing them to, the chemicals you will put them in contact with, and, most importantly, your budget. Make sure you get the valves you need at an unbeatable price!