From professional plumbers to do-it-yourselfers, there are times when you'll want to connect PEX tubing to PVC or copper pipe. The reason for this is that PEX is quickly becoming the standard material for hot and cold water lines, whereas copper and PVC are largely materials of the past. However, because PEX, copper, and PVC are as different as night and day, connecting them can be tricky.

To connect PEX to either copper or PVC, it's important to use the right fittings and tools. There are special materials specifically for connecting PEX to copper, as well as for connecting PEX to PVC. Failing to use the right adapter fittings, tools, and methods will likely result in leaks and all the issues that go along with it.

What is PEX Pipe and How is It Used?

PEX is a hard plastic tubing that was created specifically for plumbing. PEX pipe, or tubing, is made of cross-linked high-density polyethylene. As such, PEX tubing has a hard outer shell, but the way the polymers are bound together also makes it flexible, heat resistant, and extremely durable. As such, it's quickly becoming the most commonly used plumbing pipe for hot and cold water lines.

What is PVC Pipe and How is It Used?

PVC pipe, also known as polyvinyl chloride, is made from a combination of plastic and vinyl and is even harder than PEX. PVC is very durable and easy to use, but it's also inflexible and doesn't bend very easily. PVC can also become brittle over time, resulting in leaks and cracks. While it was once commonly used for hot and cold water lines, it is now typically only used for plumbing vents and drains.

What is Copper Pipe, and How is It Used?

Copper pipe is one of the oldest types of plumbing pipe still used today. Made almost entirely from pure copper, this type of pipe is hard and durable and can withstand a wide range of elements, including heat. However, copper is also extremely expensive and prone to corrosion, which means that it's used sparingly in modern plumbing.

Why You Might Need to Connect PEX to Copper or PVC

Although PEX has been around since the 1960s, it was originally only used for radiant heat. It wasn't until the 80s, 90s, and 2000s that PEX pipes started getting used for hot and cold water lines in residential and commercial plumbing. Up to that point, PVC and copper had been the materials of choice.

Because PEX has largely replaced copper and PVC in the plumbing industry, it's common during remodels and repairs to adapt PEX to these materials. Making the switch is faster, easier, cheaper, and better than using PVC or copper.

Tools You'll Need For the Job

The tools you'll need to connect PEX to PVC or copper will vary depending on the fittings you're using and what type of pipe you're connecting to.

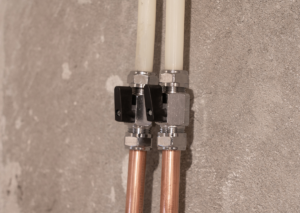

PEX to Copper

•Copper pipe cutter

•Deburring tool

•Soldering kit (optional)

•Tubing cutter

•Crimp fittings

•Crimping tool

•Clamp fittings (optional)

PEX to PVC

•PVC pipe cutter

•Cement

•Primer

•Tubing cutter

•Crimp fittings

•Crimping tool

•Clamp fittings (optional)

How to Connect PEX to PVC

If you need to connect PEX tubing to PVC, there are several ways to do so. However, it's important to remember that code restrictions are different in various cities, counties, and states. Therefore, make sure the following method is allowed in your area, or if you need to use different materials to be compliant.

Use a PEX to PVC Adapter Fitting

The cheapest way to connect PEX to PVC is to use special adapter fittings. For instance, if you need to connect 1/2" PEX pipe to 1/2" PVC, you'll need a 1/2" adapter. Here's how it works:

1. Cut the PVC pipe at the proper spot for the connection.

2. Use cement and primer to clean and prepare the PVC surface for the PVC adapter.

3. If you're using a PVC female fitting, slide the male end of the pipe inside the female end. If you're using a male fitting, slide the male end inside the female coupler end of the pipe.

4. Twist the pipe a quarter-turn and hold it in place until the cement solidifies.

5. Next, put your crimp ring around the PEX pipe that you plan to connect to.

6. Slide the PEX end of the fitting inside the PEX pipe and use your crimping tool to tighten the crimp ring on top of the PEX fitting.

How to Connect PEX to Copper

As with connecting PEX to PVC, there are several ways to connect PEX to copper. However, as with adapting PEX to copper, code requirements differ in various areas, so make sure the following method is allowed in your area before performing it.

Use a PEX to Copper Adapter Fitting

We'll use the same example above where you need to connect 1/2" PEX to 1/2" copper:

1. Use your pipe-cutting tool to cut the copper at the appropriate spot.

2. Use your deburring tool to clean the inside of the pipe and your abrasive cloth to clean the outside.

3. Apply flux to the outside of the copper pipe.

4. Clean and apply flux to the inside of the female end of the copper-to-PEX adapter.

5. Solder the pipe and adapter together.

6. Give the pipe time to cool off, then put your crimp ring around the PEX pipe that you plan to connect to the copper.

7. Slide the PEX end of the fitting inside the PEX pipe and use your crimping tool to tighten the crimp ring on top of the PEX fitting.

Use Sharkbite Fittings to Connect PEX to Copper or PVC

The fastest and easiest way to connect PEX to either PVC or copper pipe is to use a Sharkbite transition coupling/fitting. Sharkbite fittings are special push-fit fittings that are ridiculously easy to use. As long as you have the right size fitting for your connection, the connection takes seconds. Simply push the male ends of either pipe into the female ends of the Sharkbite fitting, and you're good to go.

Sharkbite fittings are also code-compliant, so you can use them anywhere!

Tips For a Leak-Free and Watertight Connection

Connecting PEX to PVC or copper pipe isn't difficult as long as you use the right tools and materials. It's also important to take your time and ensure that the male ends of your pipes are always pressed as far into the adapter fittings as possible. As long as you do these simple things, you're sure to have a watertight seal every time.